Custom protection

What is it?

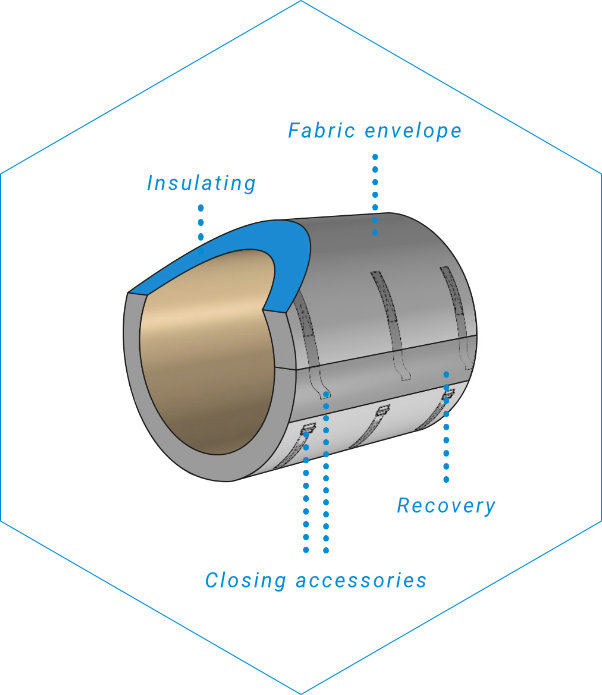

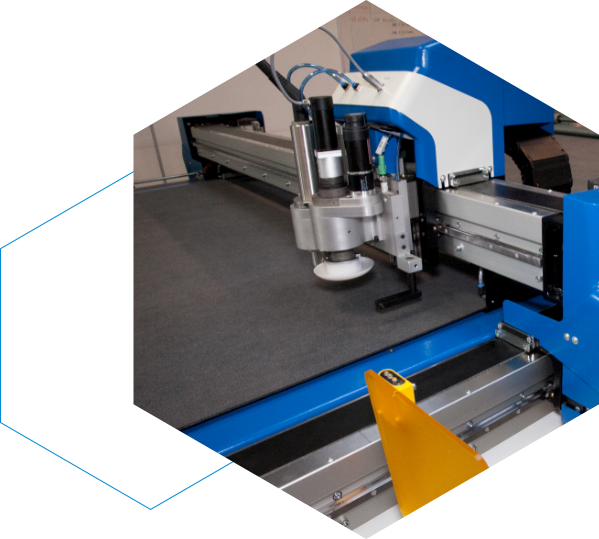

It is a flexible product composed of an insulating material wrapped in one or more technical fabrics.

Made to measure, the mattresses are installed in addition to or as a replacement for the rigid thermal insulation and adapt to the most complex shapes.

They guarantee THERMAL and PHONIC protection for the installations (by limiting the heat and acoustic losses) and for the workers (avoiding the risk of burns, hearing damage or shocks).